MotionTech UK automates insect farming technology beneath London's railway arches

| Customer name | Entocycle |

|---|---|

| Industry | Insect Farming Technology |

| Location | London, United Kingdom |

Entocycle, a leading insect farming technology provider, is pioneering cutting-edge breeding and production processes to establish insect farming as a viable global industry. To support its growth ambitions, Entocycle set out to create a 'Centre for Insect Technology' beneath the railway arches at London Bridge – combining its R&D operations with a showroom to demonstrate its unique insect farming ecosystem to investors and customers.

Challenge

To bring this vision to life, Entocycle required a fully automated solution capable of handling nine distinct breeding and production stages within an extremely space-constrained environment. MotionTech was selected as the automation partner to deliver on this ambition.

Building beneath railway arches offered visibility and prestige, but posed a complex technical puzzle. Low ceilings and structural pillars significantly limited the available space, while the automation system had to manage two separate processes, each with unique breeding and production requirements.

Full automation was essential to eliminate manual handling and prevent contamination risks, requiring the system to operate entirely behind secure mesh barriers. High-humidity and water exposure further demanded strict food-grade materials to ensure durability and compliance.

Flexibility was equally crucial. As a growing company, Entocycle needed a system that could scale without fundamental redesign.

"We found that MotionTech is willing to take decisive action when it needs to be taken, but it's also a company that is able to service what we're doing today and our ambitions."

Solution

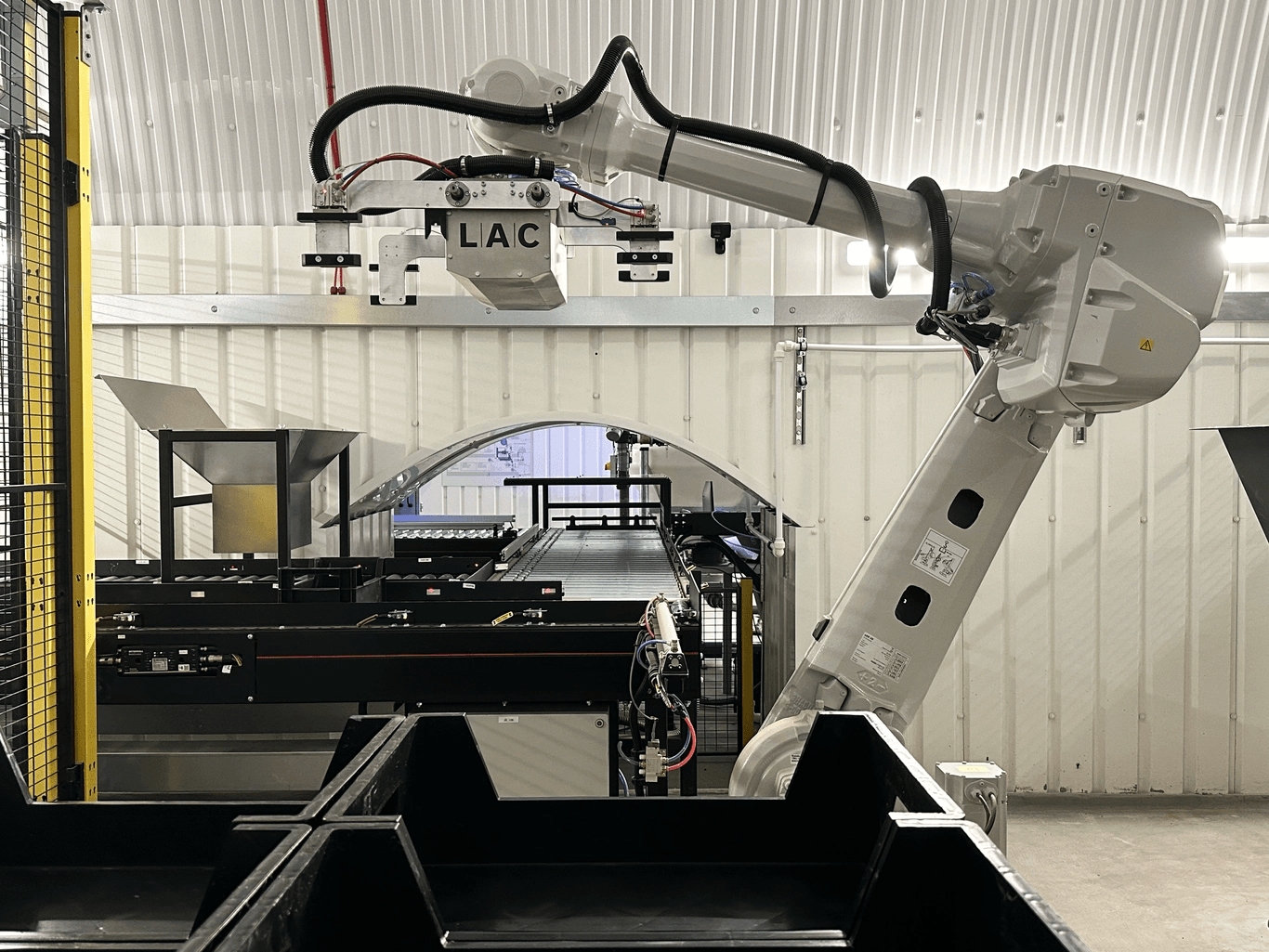

Working closely with Entocycle, MotionTech designed and installed a purpose-built automated system tailored to the site’s constraints and operational needs. The solution integrates zero-line pressure roller conveyors, an incline belt conveyor, weighing modules, sensors, controls, and a six-axis robot with specially designed grippers.

Every component was engineered to operate within low ceilings, pillars, and tight access conditions, while remaining fully automated and enclosed behind protective mesh fencing to minimise manual handling and contamination risk.

Automated workflows manage both daily breeding and monthly production cycles, from crate handling, feeding, and larvae introduction through to transfer, separation, and palletisation. As insects develop, the robot transfers them between nursery and adult crates using size-specific grippers and an integrated funnel mechanism.

A range of custom design elements – including specialised pushers, belt pop-ups, and angled conveyor sections enable efficient crate movement throughout the facility.

Result

The result is a flexible, scalable automation solution that reliably manages complex breeding and production processes, while also acting as a live demonstration of Entocycle's technology for customers and investors alike. The system’s modular design allows it to evolve alongside Entocycle’s technological and production needs. As Paul Hillman notes:

"Having a system that is modular allows us to change things in a year, two years, or three years without having to rip everything up and start again.”

The 'Centre for Insect Technology' positions Entocycle to communicate their capabilities and potential to key stakeholders, supported by MotionTech's automation expertise and engineering solutions designed specifically for their growth trajectory.”