Powerful facility for Tamro

| Customer name | Tamro |

|---|---|

| Industry | Pharma & healthcare |

| Location | Stockholm, Sweden |

Tamro’s blue crates are a familiar sight in Swedish pharmacies and hospitals. Next year will see major improvements in the internal handling of the trays at Tamro’s distribution warehouse south of Stockholm.

Free up space in the warehouse.

Every day, around 10,000 blue crates are sent out to pharmacies and hospitals from Tamro's facility in Kungens Kurva, south of Stockholm.

Improved handling of empty plastic crates and lids.

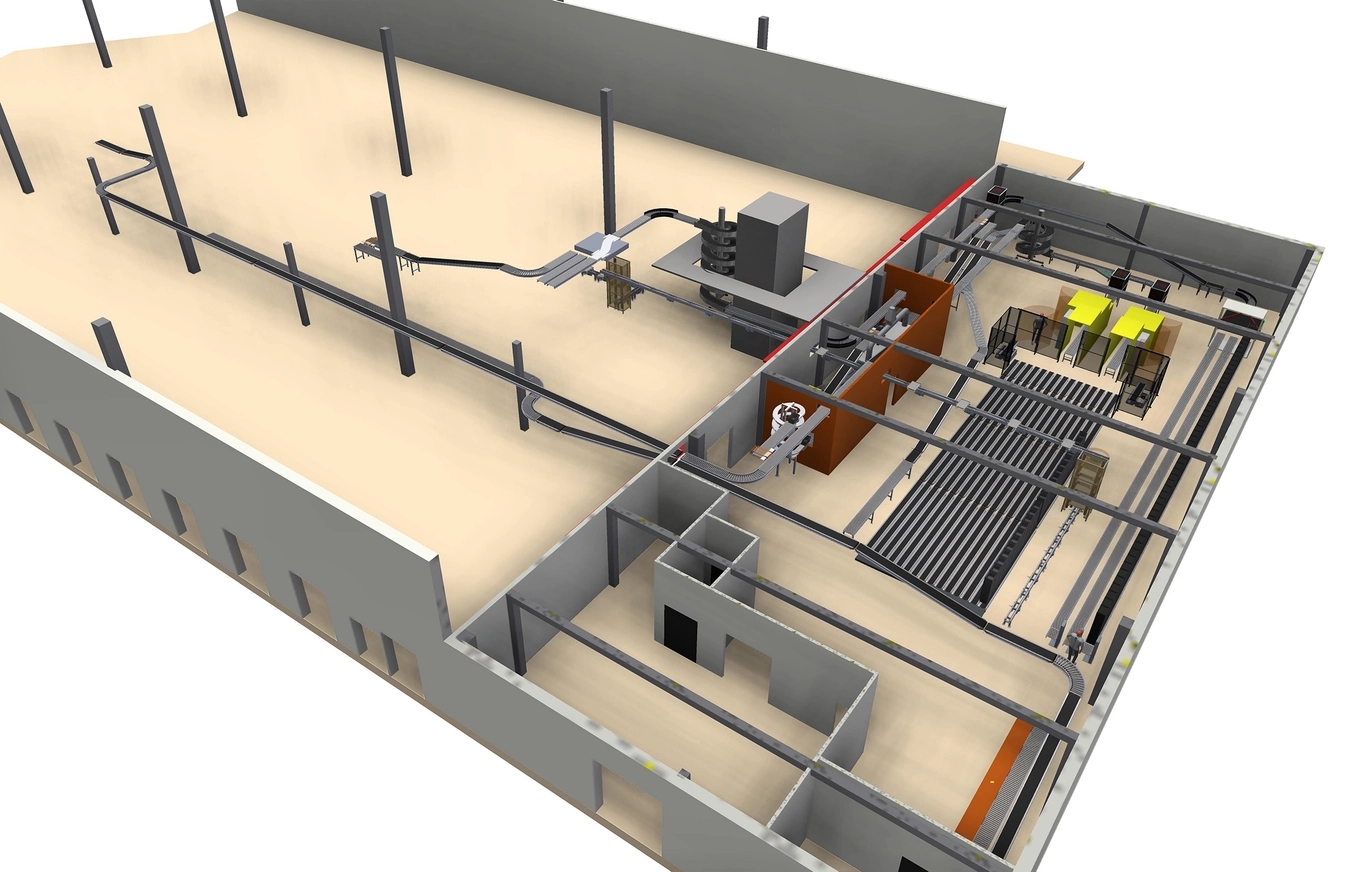

Sketch of the new facility at Tamro in Kungens Kurva. The facility consists of conveyor belts, buffer storage for crates, and spiral elevators for lid placement, all integrated with the rest of the flow of orders.

Result

The number of deliveries per hour increases from 1,800 to 3,000.

Improved handling of empty crates and lids

When it comes to pharmaceuticals, it is easy to understand that the flow of goods is critical. Swedish pharmaceutical wholesaler Tamro has been handling this for 100 years. From its logistics center in Kungens Kurva, south of Stockholm, it supplies pharmacies and hospitals with around 10,000 deliveries every day, or up to 15,000 at peak times. The goods are packed in blue plastic crates with lids and taken to the pharmacy, where conveyor belts take the empty crates back.

Tamro recently signed an agreement with ITO PallPack for the delivery of a new facility for handling and buffering empty plastic crates and lids. The facility will be installed by spring 2025. Per-Erik Pettersson is responsible for the production development of internal transports at Tamro's facility in Kungens Kurva. He says that the investment will bring several benefits.

"Today, we have a number of older solutions that have reached the end of their technical life. With the new facility, we will be able to move the empty crates to a new area, freeing up space for deliveries. The order flow will improve, the storage of empty crates will become more space-efficient, crates without lids will be transported efficiently to where the goods are filled, and before delivery, the lids will be transported by spiral lift to level 2, where they will be put on and strapped. This will be a modern facility that will increase both operational reliability and our efficiency," says Per-Erik Pettersson.

From 1,800 to 3,000 orders per hour

The efficiency gains will come from increased storage capacity for empty pallets and, not least, from an increase in the number of deliveries per hour from the current 1,800 to 3,000.

“This is almost a doubling of capacity and will undoubtedly mean a lot to us,” says Per-Erik Pettersson.

"This is almost a doubling of capacity and will undoubtedly mean a lot to us”

Why did you choose ITO PallPack as your partner for this upgrade?

"It was an easy choice because they presented the best solution. Plus, it's easy to communicate with Scandinavians. It has been good working with ITO PallPack, and we've collaborated on designing the technical aspects. Expectations here are high, so it's going to be an exciting spring before everything hopefully gets up and running by summer 2025," Per-Erik Pettersson concludes.