Products

MotionTech delivers leading-edge automation solutions that transform material handling operations. From advanced conveyor systems to smart storage and picking solutions, our comprehensive product range combines innovation with reliability. We tailor our products to your specific needs, ensuring smooth integration and durable performance.

Conveyors

We provide high-performance conveyor solutions that enhance material flow in modern production, warehouse, and intralogistics facilities. Our modular and scalable systems handle all types of goods – from lightweight packages to heavy pallets.

Discover more about our conveyors at:

Product range

- Belt conveyors

- Belt flat curve conveyors

- Roller conveyors

- Chain conveyors

- Vertical conveyors (Lifts/spiral)

- Overhead conveyors

- Belt merge & divert

High throughput rates for improved operational efficiency

Minimal downtime during belt, pulley and bearing replacement

Flexible solutions for all load types – from lightweight containers to heavy pallets

Optimised space utilisation through vertical and horizontal configurations

Ergonomic design that improves workplace safety

Seamless integration with existing automation systems

Key benefits

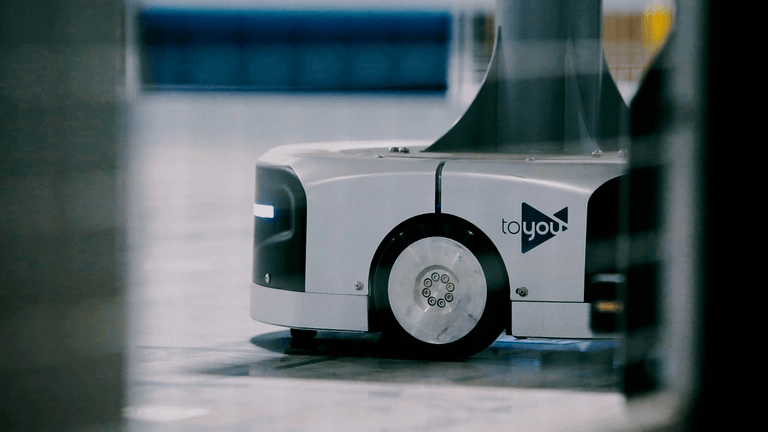

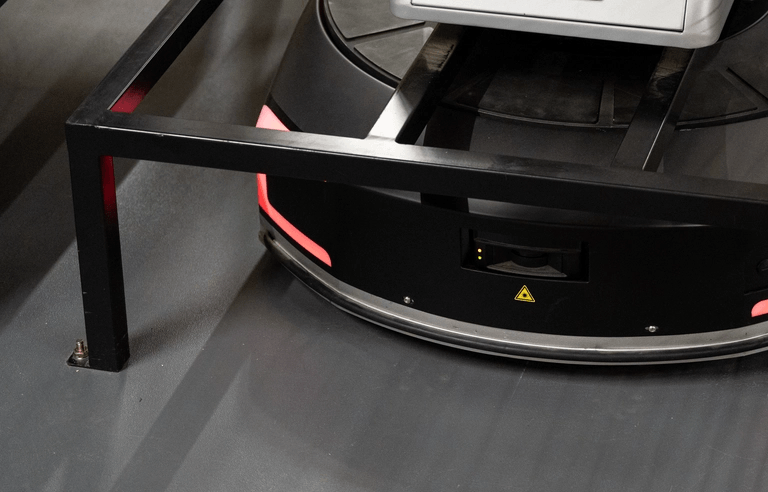

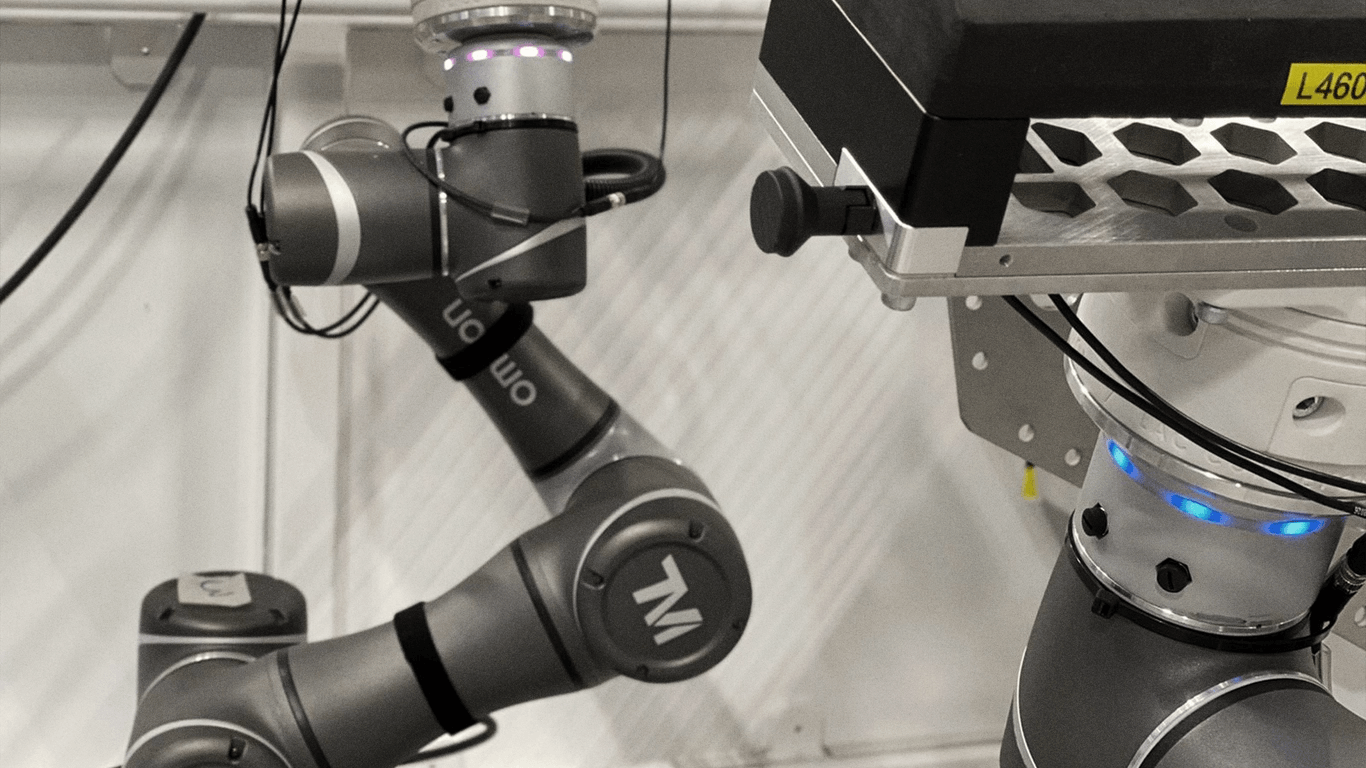

AGV & AMR

MotionTech provides intelligent transport automation through Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). Our AGVs move materials safely along fixed paths, while our AMRs adapt to their environment using AI and advanced sensors for dynamic navigation. We implement robust automation solutions that boost efficiency in production, warehouse and intralogistics operations.

Discover more about our AGV & AMR at:

Product range

- Goods-to-person

- Point-to-point transport

Flexible navigation options – predefined paths or dynamic AI routing

Enhanced order picking accuracy and inventory management

Safe and efficient human-robot collaboration

Robust design for diverse industrial environments

Reduced operational costs and manual handling risks

Key benefits

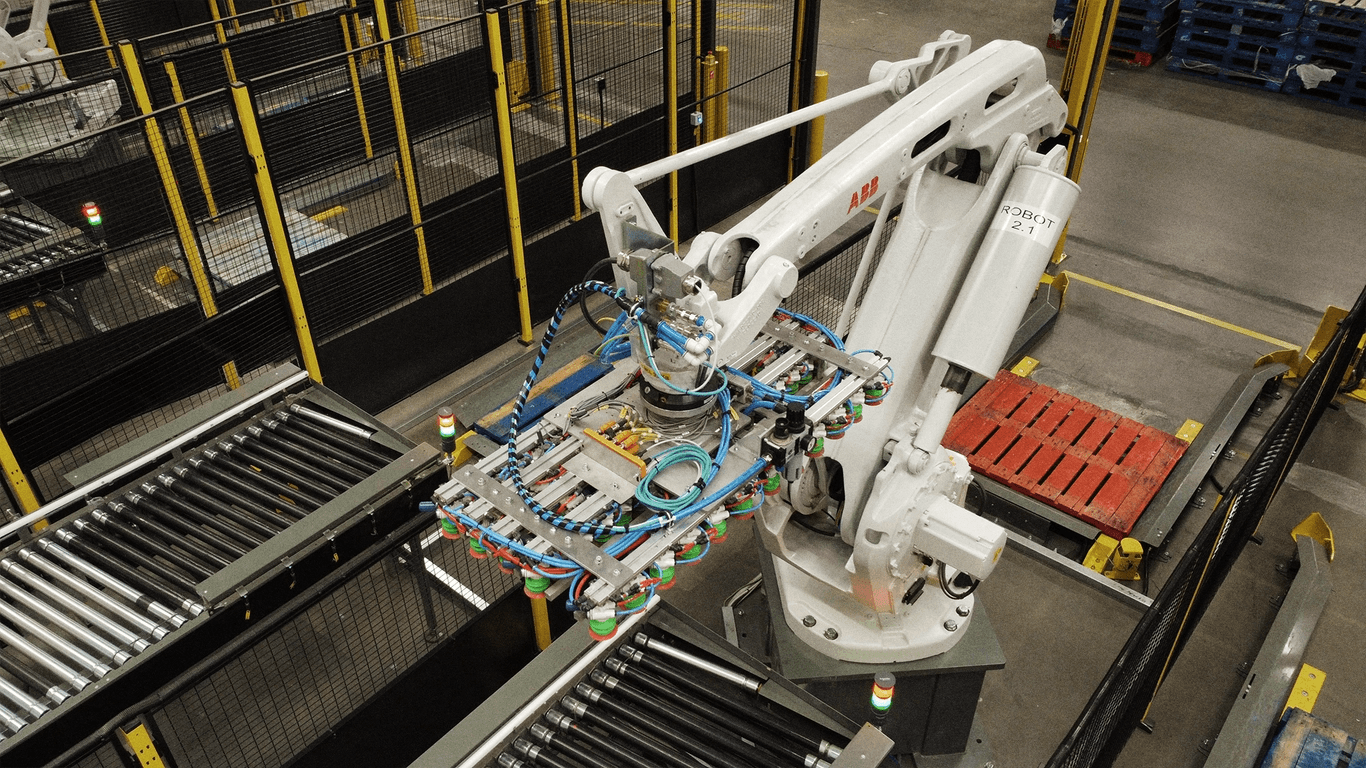

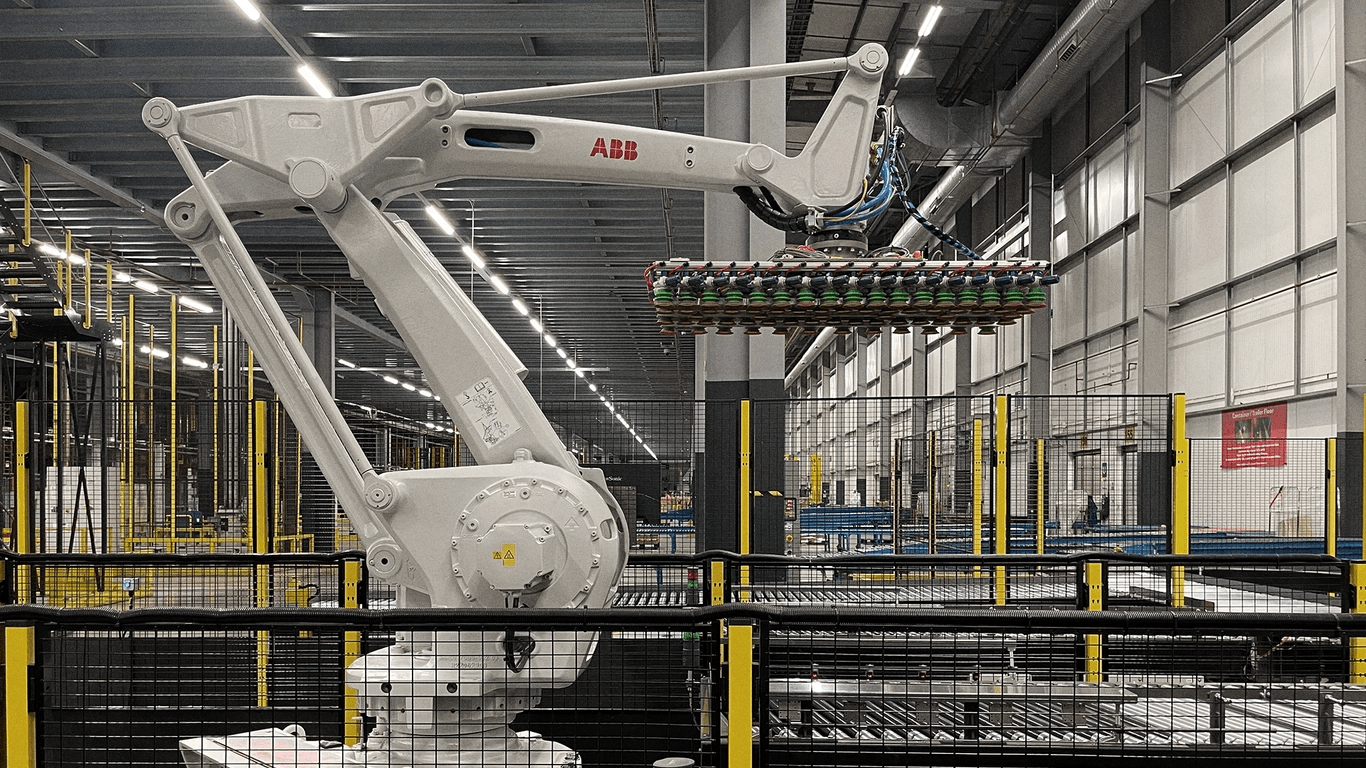

Palletisers

Our high-performance palletising systems automate the stacking of boxes, bags, and cases onto pallets with precision and reliability. Working with leading robot manufacturers such as ABB, Fanuc, Kawasaki, Kuka and Yaskawa, we configure systems that match your exact requirements. For layer palletising, we offer proven range of machines, designed for high product flow.

Discover more about our palletisers at:

Product range

- Robot palletising systems

- Robot de-palletising systems

- Layer palletising solutions

- Bespoke palletising applications

High-precision automated stacking

Adaptable to various product lines and sizes

Flexible programming for diverse pallet patterns and flow

Increased throughput and workplace safety

Food-grade options with stainless steel robots

Key benefits

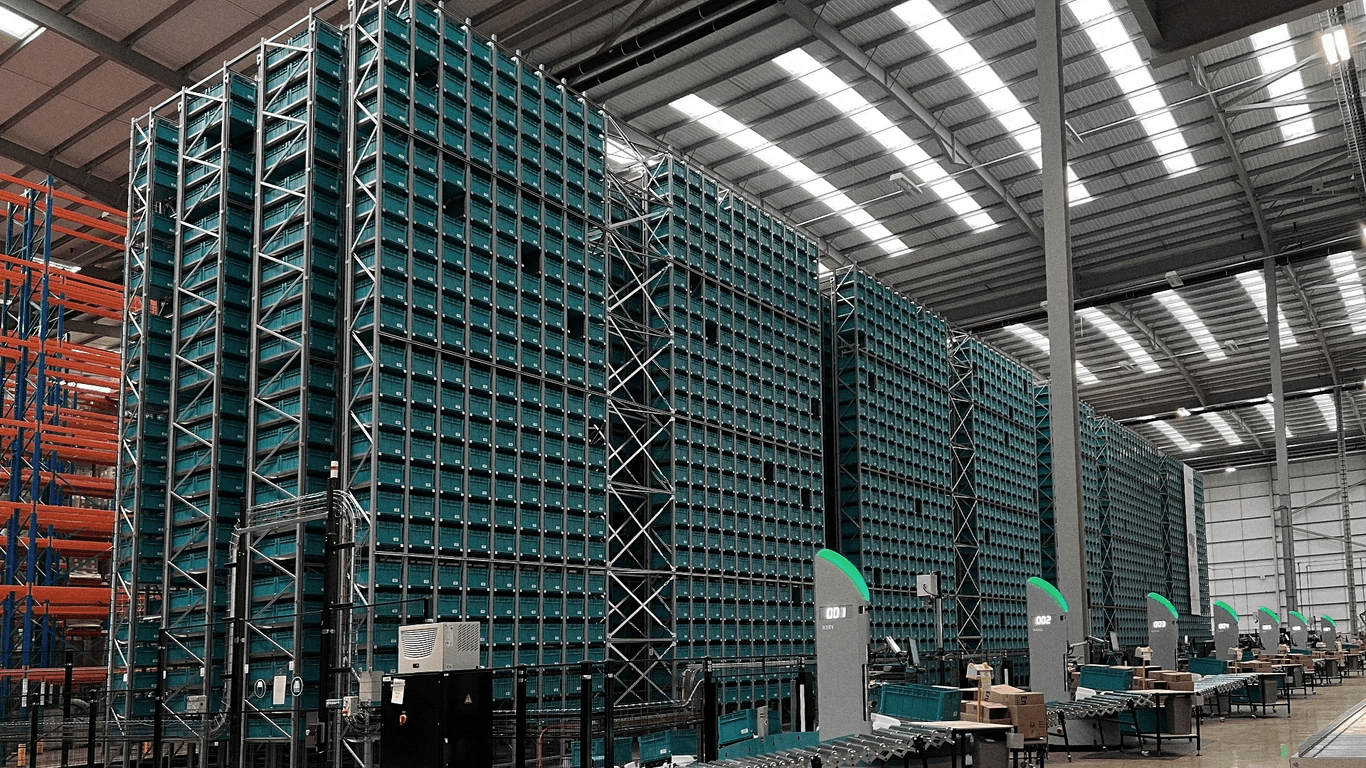

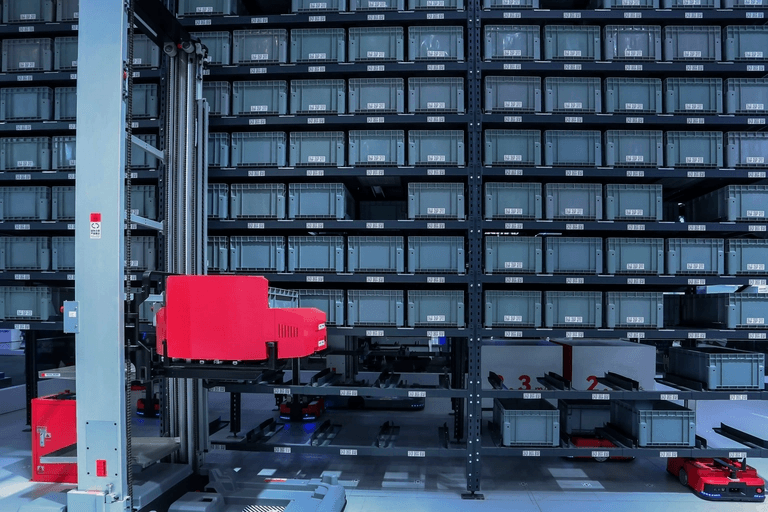

ASRS & Storage systems

Our Automated Storage and Retrieval Systems (ASRS) upgrade production, warehouse, and intralogistics operations through efficient handling of all goods – from small components to full pallets. By combining vertical storage with intelligent control systems, we help you maximise space utilisation while increasing output and inventory accuracy.

Discover more about our ASRS & Storage systems at:

Product range

- Mini-load system

- Pallet storage system

- Pallet shuttle system

- Nekos LT storage solution

Maximum storage density through vertical space utilisation

Accurate, high-speed retrieval that meet demanding throughput requirements

Real-time inventory management for improved control and tracking

Reduced operational costs and manual handling

Modular and scalable designs for growing operations

Key benefits

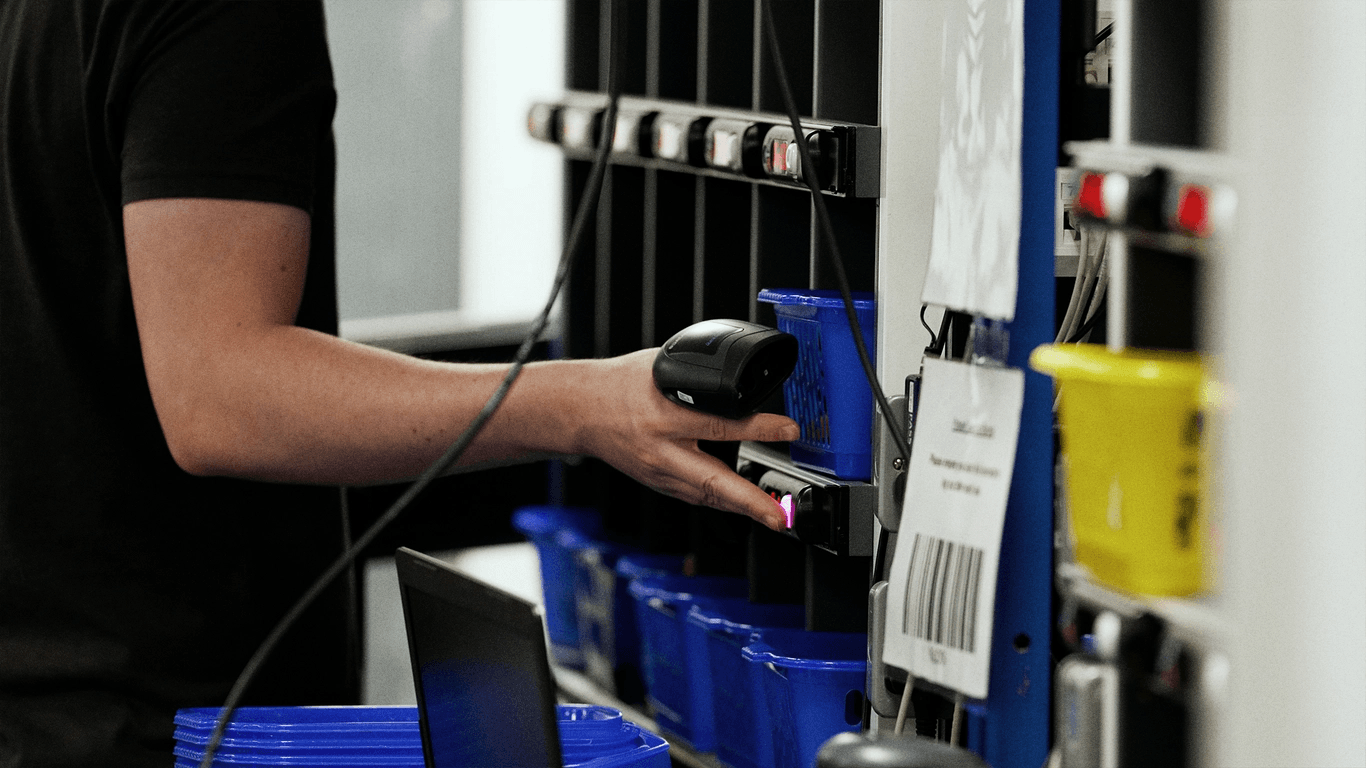

Picking systems

MotionTech improves order fulfilment through advanced robotic picking solutions. We integrate multiple robot types, such as Articulated, Delta, SCARA, and Cartesian – to create efficient pick, pack, and place operations. Working with leading manufacturers including ABB, Fanuc, Kawasaki, KUKA, and Staubli, we design systems that enhance accuracy and speed while reducing operational costs in warehouses, distribution, and production facilities.

Discover more about our picking systems at:

Product range

- Robotic pick and place systems

- Vision-guided picking solutions

- Pack and palletising integration

- Custom picking applications

Flexible and modular for diverse warehouse needs

Advanced vision systems for accurate product identification

Reduced labour costs and picking errors

Compatible with existing automation systems

Increased throughput and productivity

Key benefits

Sortation systems

MotionTech sortation systems process diverse products with precision and speed. Our solutions handle everything from parcels and polybags to large mail items, achieving throughput rates up to 15,000 units per hour. We implement horizontal and vertical cross belt sorters throughout your facility – from goods receiving to picking and shipping areas. Through our partnership with Interroll and integration with mobile robots or shuttle systems, we boost sorting capabilities while offering flexible storage and sequencing options.

Discover more about our sortation systems at:

Product range

- We offer a complete range of equipment for all sortation operations

High-speed processing up to 15,000 units per hour

Improved order accuracy and fulfilment rates

Handles diverse product types and sizes

Seamless integration with warehouse management systems (WMS)

Scalable design for future growth

Key benefits

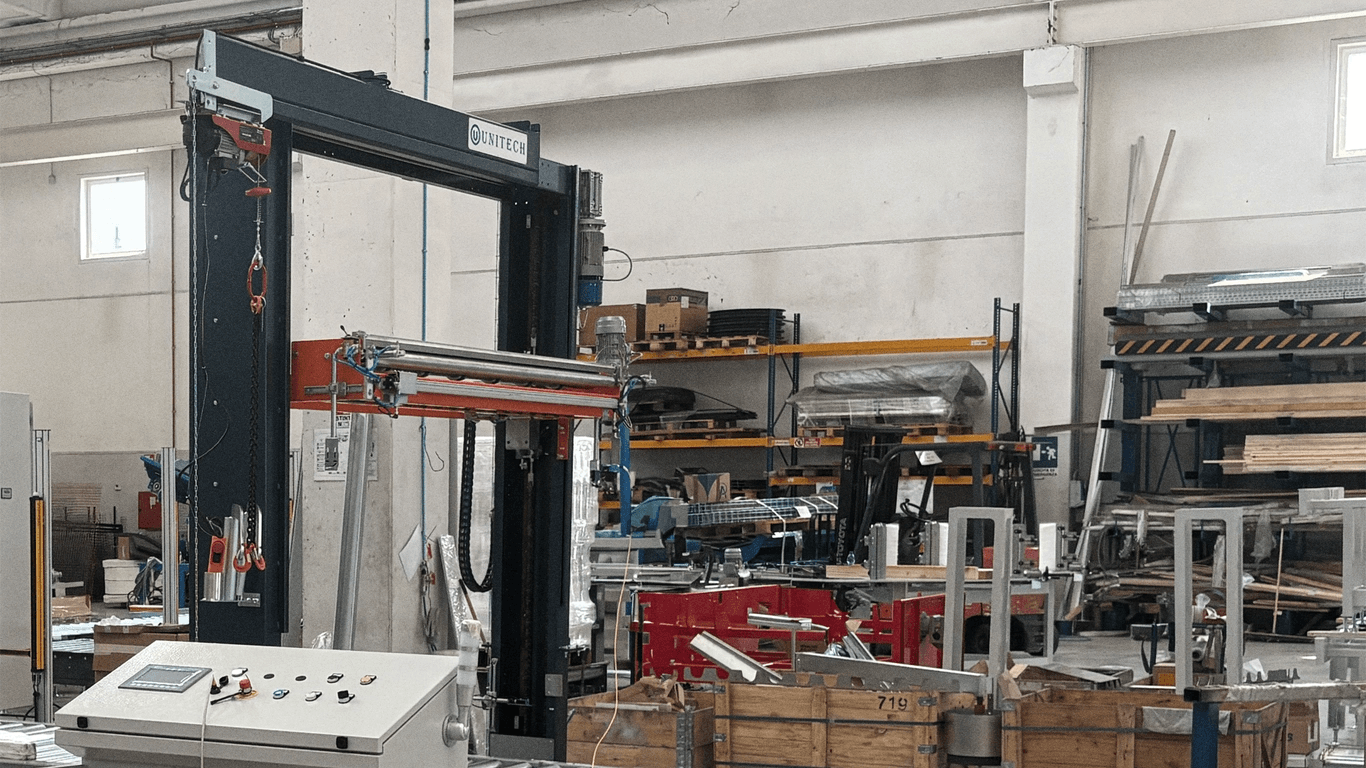

Secondary packaging

MotionTech optimises product preparation for shipment through efficient packaging automation. Built on expertise from Unitech Packaging and ITO PallPack, our solutions automate wrapping, strapping, and boxing processes while reducing manual handling. We design systems that integrate with your existing conveyor and palletising operations to create a continuous packaging workflow.

Discover more about our secondary packaging at:

Product range

- Strapping systems

- Packaging machines

- Stretch film solutions

- Carton erectors

- Custom packaging solutions

Increased packaging speed and output

Reduced manual handling requirements

Energy-efficient operations

Reliable equipment with durable design and long-service life

Modular design and complete system integration capabilities

Key benefits

Safety products

MotionTech protects your operations with extensive safety and support solutions. We design and implement control panels that meet strict safety standards while monitoring system performance. Our expert team provides continuous support through remote diagnostics, preventive maintenance, and system upgrades to minimise risks and maintain optimal operation of your automation equipment.

Discover more about our safety products at:

Product range

- Safety sensors and scanners

- Area protection devices

- Warning & communication systems

- Training, digital safety tools and safety control panels

Protects workers from accidents and injuries, creating a safer work environment

Prevents damage to equipment and goods, reducing downtime and repair costs

Enables safe human-machine collaboration, especially with robots and AMRs

Reduces liability risks by meeting health and safety regulations

Improves operational efficiency through safe, uninterrupted operations

Key benefits

Manufacturing automation

Businesses are increasingly adopting automation strategies that span the entire value chain from raw material intake to final delivery. MotionTech is expanding its automation expertise into the manufacturing sector with solutions that enhance precision, reliability, and throughput.

Our focus includes material handling and primary packaging systems, forming the foundation for smart, connected, and hygienic production. With the use of robotics, AMRs, and AS/RS buffer storage, we support continuous manufacturing flows even when shipping operates on limited schedules. Through scalable systems that connect production, warehouse, and intralogistics facilities, MotionTech helps your business run smarter and achieve more.

Product range

- Material handling systems

- Primary packaging systems (filling, capping, wrapping, sealing)

- Robotics and AMR solutions for production flow

- AS/RS and buffer storage integration

- Line control and system integration solutions

Improved precision, reliability, and throughput

Continuous production flow and reduced downtime

Seamless connection between production, warehouse, and intralogistics

Hygienic, efficient, and flexible automation solutions

Scalable systems that help your business run smarter

Key benefits

Featured customer cases

Our goal is to make businesses thrive by making motion smarter. Discover how we enable clients to cut costs while increasing efficiency and driving growth.

Industries we serve

Each industry faces distinct challenges in today's dynamic market. Our solutions are specifically designed to address the unique requirements of each sector, combining leading-edge technology with deep sector expertise. We focus on enhancing operational efficiency, driving growth, and establishing competitive advantages through tailored supply chain solutions.

Ensure food safety and freshness with our specialised automation solutions. Our systems handle temperature-sensitive products efficiently, maintain traceability, and maximise storage space while reducing waste in your food and beverage operations.

Meet the demands of modern grocery with solutions that handle everything from ambient to temperature-controlled items. Our systems enable efficient online order fulfilment while supporting traditional store replenishment, helping you stay competitive in a rapidly evolving market.

Elevate your merchandise operations with automation that puts products where they need to be. Our systems help you manage complex inventories, reduce stockouts, and enable omnichannel fulfilment – keeping your customers satisfied across all channels.

Keep pace with rapidly changing consumer demands through flexible automation. Our scalable solutions help you handle peak seasons effortlessly, reduce order processing times, and maintain accuracy – ensuring customer satisfaction in the competitive digital marketplace.

Meet strict regulatory requirements while ensuring precise inventory control. Our automated solutions provide the traceability, accuracy, and reliability crucial for pharmaceutical and healthcare logistics, helping you maintain product integrity and patient safety.

Transform your production flow with our integrated automation systems. From component handling to final assembly, we optimise every step of your manufacturing process, reducing waste and enabling smart, sustainable operations that drive productivity.

Overcome the challenges of modern delivery with our smart sorting and handling solutions. We help you process higher volumes faster, reduce manual handling, and maintain accuracy across your entire intralogistics operation.

Improve your logistics operations with smart automation that adapts to changing demands. Our solutions help you reduce labour dependencies, increase throughput, and provide real-time visibility – enabling you to deliver exceptional service while maintaining competitive margins.

Optimise your airport operations with belt flat curve conveyors, allowing for rapid belt removal and easy maintenance. Our conveyor solutions deliver advanced detection and safety features that minimise disruption to valuable operation time, cut noise, and ensure every bag gets where it needs to go – at a lower total cost of operation.